A Digital Twin of Your Power System

The data foundation for future-proof decision-making

Imagine planning your power system with complete clarity – no guesswork, no scattered data slowing you down.

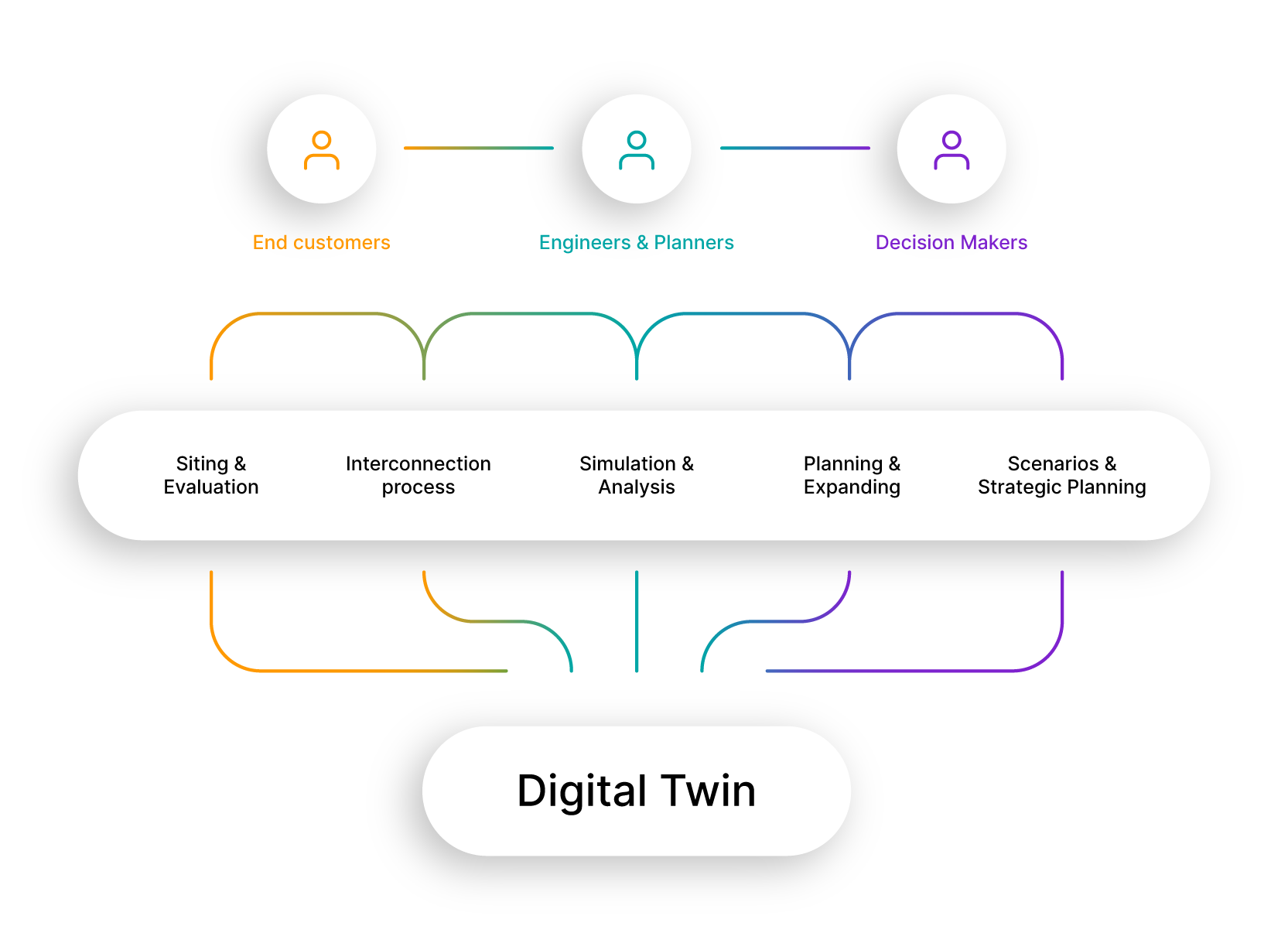

The IGP digital twin creates a single, simulation-ready replica of your network, so every decision in planning and operations is confident and informed.

“We have the data but it's spread across five different systems.“ That’s a line we hear from utilities again and again.

GIS, AMI, SCADA, and workflow tools each show only part of the picture. Many describe it like a puzzle with pieces from different boxes. Nothing fits together.

This is where the digital twin makes the difference. It brings together everything that is often siloed, including network topology, assets, load profiles, and measurement data, into a single, consistent model ready for simulations and analysis. No more patchwork. Just a complete view of your distribution system complete with power flow analysis, updated on a daily basis.

This foundation makes digital processes like interconnection, grid planning, and asset management possible.

It is this shared understanding that drives the results our customers rely on.

How is the digital twin created at envelio?

1) The Data Shipper Framework: Data Modeling and Preparation

To build a high-fidelity digital twin, the IGP requires detailed input data that reflects what is actually happening on the network, including:

- Grid topology and geo data – including normal switching states and feeder routes

- Asset-specific details such as location, type, capacity, and current-carrying capability of cables, substations, and transformers

- Information on network participants such as solar systems, EV chargers, or heat pumps – including technical parameters and interconnection details

These data points are collected from different source systems, including GIS, asset management systems, and smart meter backends, and then united via the IGP Data Shipper.

2) The Data Shipper Framework: Flexible Interfaces for System Integration

To keep the digital twin up to date, data needs to flow regularly and reliably from all source systems. Standard format like CIM or CGMES are helpful, but in practice, they are more guidelines than strict standards. As a result, true plug-and-play data exchange remains difficult.

That’s why we take a different approach at envelio: The IGP modular Data Shipper Framework integrates each customer’s systems through standardized, reusable modules that are individually tailored. This ensures a stable, transparent integration process without the need for manual data prep.

We handle the full implementation – from interface setup and data processing to delivery into the IGP. All the utility needs to do is provide access to the data – in any format.

Thanks to this framework, we’ve successfully integrated nearly 100 different systems to date, including GIS, AMI, and SCADA systems.

The result is a reliable and scalable data pipeline – automated, transparent, and built around your needs.

3) The Data Shipper Framework: Ensuring High-Quality Data

The reliability of a network model often only becomes clear when looking at the complete picture. Individual datasets may seem fine on their own, but errors often appear once everything is combined in the digital twin.

That’s why envelio applies a two-stage quality control approach:

1. Pre-checks before model creationThe IGP automatically checks every dataset for completeness and plausibility. Inconsistencies – like unrealistic transformer capacities or missing mandatory fields – are flagged, and many of them can be corrected directly by the system.

2. Validation of the complete network modelOnce the data is merged, the network structure is thoroughly validated. Are all network areas connected properly? Are there any open ends or missing links? Automated checks – such as system tracing and load flow simulations – are applied at this stage. These checks help systematically uncover critical issues like non-converging networks or unrealistic loadings.

Errors aren’t just logged – they’re documented and re-checked with every new import. This enables targeted corrections in the source systems, benefiting not only the IGP but also other platforms across the organization.

4) The GridHub: Grid model version management orchestrating all layers of the model

The Core Component: The Grid Hub is the foundation of the IGP, integrating seamlessly into existing data, processes, and systems. This is not a static data repository, but a dynamic, synchronized environment that continuously updates as source systems change.

All applications within the Intelligent Grid Platform access this very model ensuring consistency, version control, and central management. The Grid Hub is the place where ongoing and automated data updates resonate, enabling that every team works on the same model state. The holistic model connects built, planned and forecast domains.

This is how data turns into a practical tool

A digital twin isn’t an end in itself. Its true value comes from serving as the foundation for real processes and use cases, from strategic planning to day-to-day operations.

Scenario analyses and system planning

A complete, simulation-ready network model is essential to running realistic scenarios, identifying critical areas early, and prioritizing investments efficiently.

Automating interconnection requests evaluation

Whether it's a PV system, EV charger, or heat pump – new interconnection requests can be evaluated directly within the digital twin, quickly and in full compliance with local regulations, without unnecessary manual effort.

Grid monitoring and state estimation

Enriched with real-time measurement data, the digital twin becomes the operational backbone – supporting switching decisions, maintenance planning, and congestion detection.

PlanOps-Approach: Planning + Operations

Using a single model for planning, operations, and asset management aligns processes, speeds decision-making, and creates a more integrated approach to network management.

The planned layer: Seamlessly manage your queue and planned upgrades

Utilities must often allocate capacity long before projects go live. The digital twin from envelio helps manage that proactively.

Queued projects that are not yet interconnected, along with planned network reinforcement measures, can be added as their own layer within the model. Instead of managing this data in siloed tools, reservations and planned measures are embedded directly in the model, where they can be taken into account across all projects.

This provides clarity, avoids double-reservations, and turns the network model into a tool for proactive planning.

Curious how to optimize your data foundation for future-proof decision-making?

Book a consultation and learn how our solutions can optimize your processes!