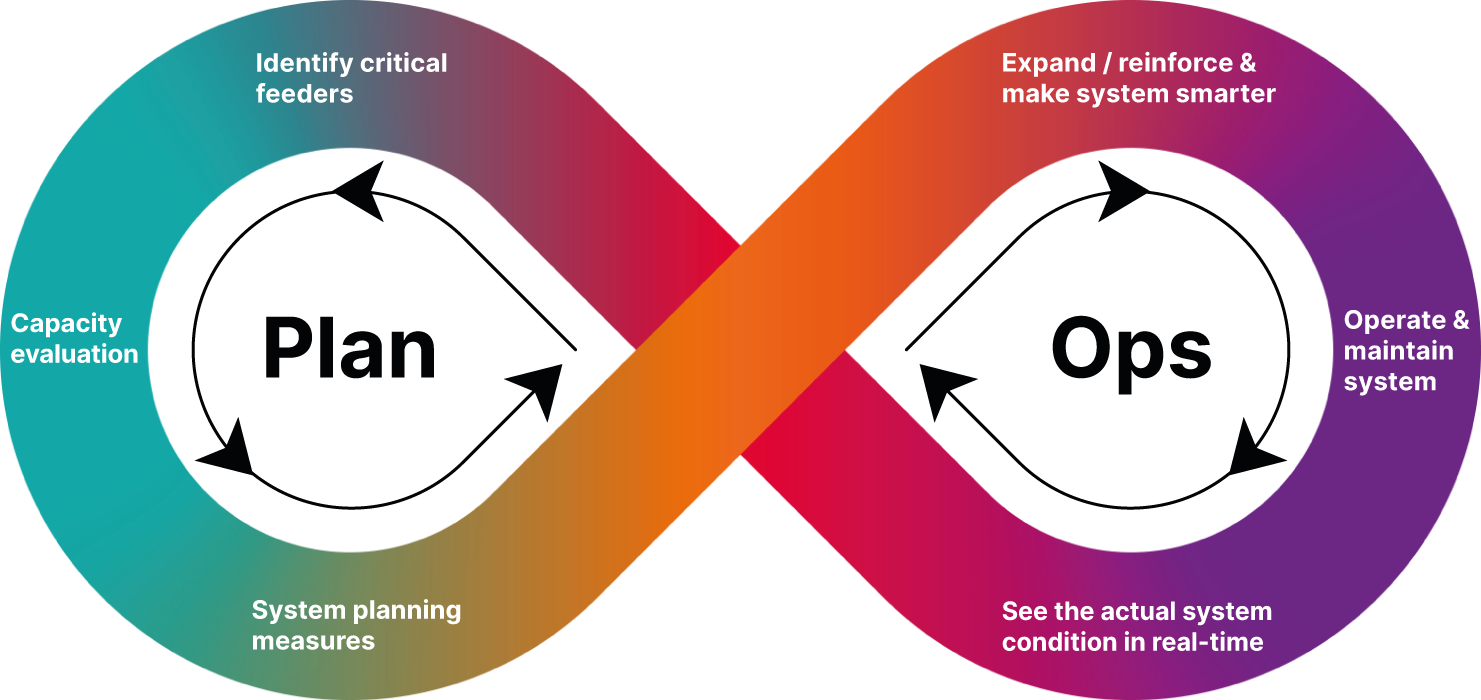

Aligning planning and operations: PlanOps

A new level of efficiency for grid planning and operations

Electrical distribution systems are under increasing pressure, yet planning, operations, and asset management teams often still act in isolation. This fragmentation leads to inefficient use of resources and misaligned decisions.

The PlanOps approach enables close coordination between these areas to better align planning processes, allocate resources more effectively, and prepare the system for the future.

Technical departments have structurally different tasks and requirements, which is why they often work separately – with their own network models, minimal data exchange, and little process alignment. In the past, this didn't pose much of a problem, because as the interdependencies between departments were not yet important. But today, networks are operating closer to technical limits, and decisions in one area directly impact others – for example, when flexibility measures can defer some short-term network expansion strategies.

The solution: The PlanOps approach

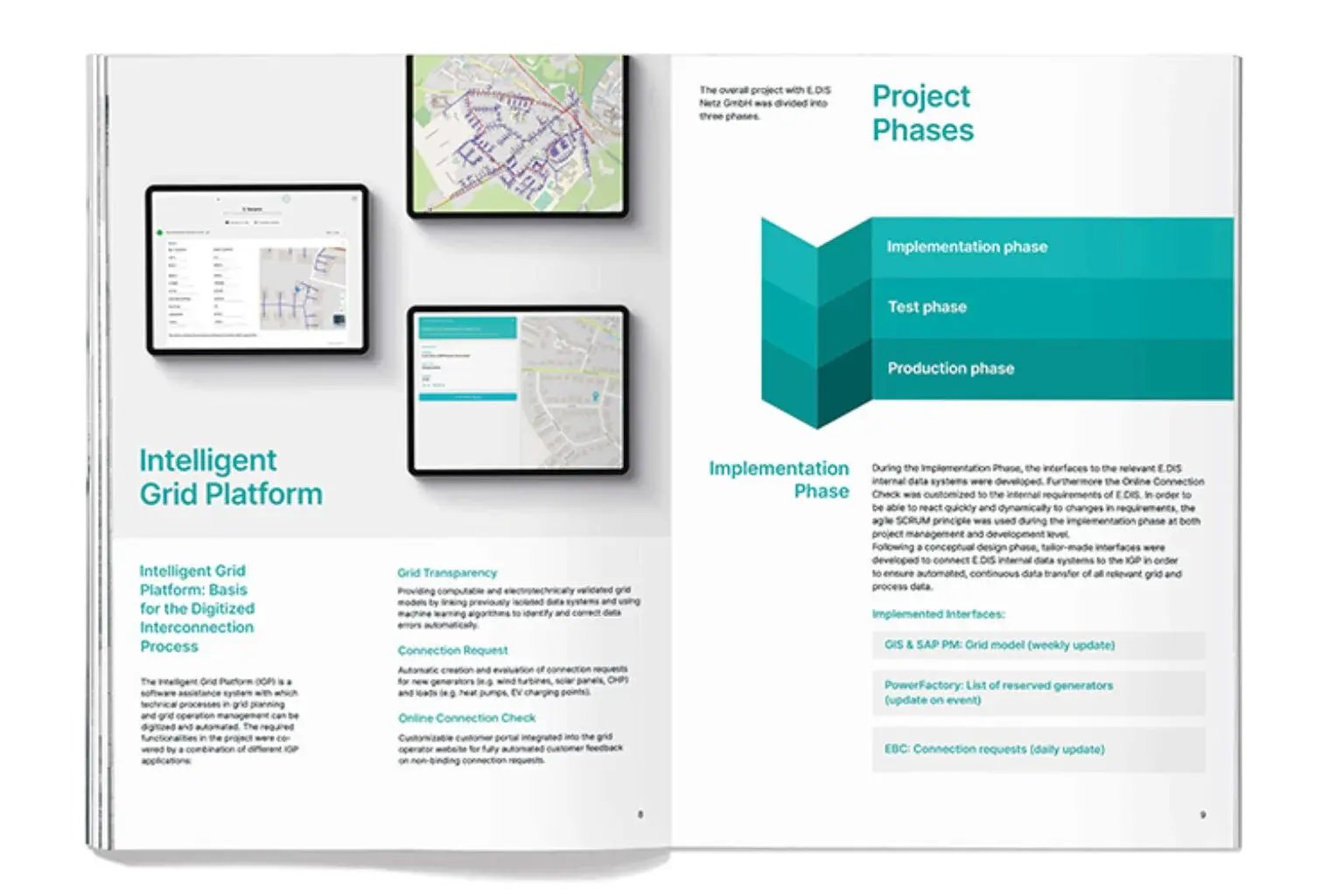

Inspired by the DevOps model from IT, PlanOps fosters continuous collaboration between system planning and operations. Its foundation is the digital twin of the grid: a unified model that is continuously updated with real-time data and made available across departments.

The PlanOps approach ensures that decisions are made more quickly, based on data, and with better coordination.

PlanOps in practice: Where this approach makes all the difference

1) More precise system planning with real-time data:

System planners make decisions every day that will impact the electrical distribution system for years. Yet these decisions are often based on static models or theoretical forecasts that don’t reflect actual conditions. Without accurate data, there’s a risk that reinforcement measures will be misprioritized or existing bottlenecks will be overlooked.

How PlanOps helps:

PlanOps ensures that planners no longer rely on assumptions but can instead incorporate live operational data. AMI / smart meter measurements and other operational data streams are integrated to build a more accurate digital representation of the distribution system. Instead of relying on safety margins, they can identify where the system is truly reaching its limits – and take targeted, data-driven action.

How this works with envelio:

- Online Monitoring provides live voltage and power flow data.

- Operative Grid Planner uses real-time data for accurate capacity evaluations.

- Grid Scenario Simulator simulates future loads.

- Grid Transparency ensures the network model is continuously updated.

2) Integrating flexibility into system planning:

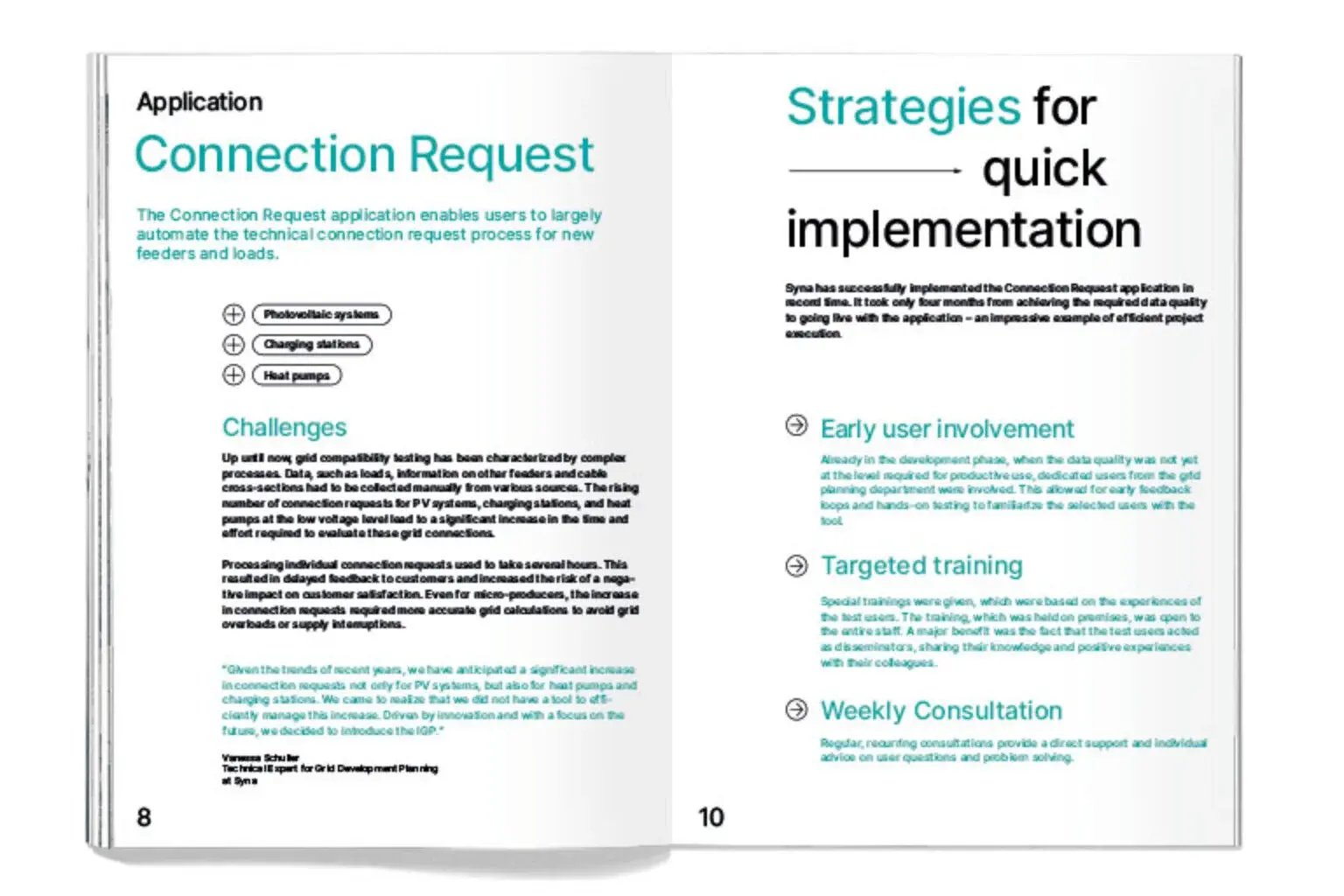

Heat pumps, EV chargers, rooftop PV, data centers – interconnection requests are growing rapidly, and planners must respond to increasing demand from large load requests. The key question is: Is network reinforcement really necessary at this point or can flexibility measures unlock enough capacity to accommodate new interconnections without immediate major investment?

How PlanOps helps:

PlanOps ensures that planners can factor in flexibility as a viable alternative. Instead of defaulting to expansion, they can first assess whether smart control measures would create sufficient capacity and allow to interconnect new consumption and generation systems without reinforcing the network first.

How this works with envelio:

Utilities can run Flexible Capacity Assessments or exploratory planning scenarios using the envelio apps:

- Grid Connection Study evaluates flexibility for specific interconnection requests.

- Operative Grid Planner compares flexibility options to traditional reinforcement.

- Grid Scenario Simulator shows the role of flexibility in projected network development.

3) Prioritizing the rollout of measurement devices for grid monitoring:

Measurement equipment is expensive and its installation takes time and skilled labor – two resources that are scarce. System analysts and asset managers must make an informed decision to determine where new measurement equipment will deliver the most value. But without reliable data, installation locations are often chosen based on fixed rules and assumptions rather than actual need.

How PlanOps helps:

With PlanOps, the deployment of measurement equipment is data driven. Instead of installing devices arbitrarily, planners can first analyze: Where do simulations based on current planning principles indicate existing overloads? Where do we expect strong growth in generation or consumption in the near or not so near future? This allows utilities to place measurement devices exactly where they will help uncover system issues early.

How this works with envelio:

- Grid Transparency analyzes load based on current planning assumptions.

- Time-Series Control Center evaluates existing measurement data to assess current network conditions.

- Grid Scenario Simulator identifies areas with expected future overloads, supporting proactive sensor deployment.

4) Preparing the system for foreseeable control measures:

Regulations differ but in many cases interconnection requests for new loads such as heat pumps and EV chargers can no longer be denied, but in some cases curtailment programs are required. This requires the right infrastructure: measurement points, communication paths, and control systems. Often, though, it’s not until the network compatibility check is performed that the need for control measures is identified – and the missing components are highlighted.

How PlanOps helps:

PlanOps informs utilities early whenever planning indicates a foreseeable need for control measures. This turns planning knowledge into operational action: Operations teams know where and when control will be required and can take early steps – from validating data to rolling out infrastructure for measuring.

How this works with envelio:

- Grid Connection Study flags early where control measures will be needed.

- Online Monitoring assesses technical controllability in each network.

- Data Manager ensures the data needed for control is available and reliable.

Curious how to bring planning and operations closer together?

Book a consultation and learn how our solutions can optimize your processes!

The advantages of PlanOps at a glance

Decisions based on real-time data

System planning is no longer based on assumptions but rather on real operational data. This way, you can predict bottlenecks early and take proactive mitigating measures.

Faster system-related measures

With closer coordination between planning and operations, system constraints are identified and prioritized sooner, enabling utility to take action exactly where it’s needed most.

Improved operational decision-making through better planning-operations alignment

Operations teams are provided with a more accurate understanding of feeder loading, DER penetration, and constraint locations. By connecting high-quality planning insights, hosting capacity transparency, and validated grid models to existing OMS/ADMS or DERMS workflows, utilities can reduce delays and errors in network management.

Less coordination effort between teams

All relevant data flows into a central network model. Manual processes are reduced, and interconnection assessments and expansion decisions are made faster.

Explore further

Case study: The Strategies of Readying Helsinki’s Power Grid for 2030 with envelio

Case study: Introducing a POI self-checker for end customers at E.DIS

White Paper: Scaling the Distribution

Interconnection Process